Unexpectedly

cardboard

A matter of genius

30.136.986

boxes every day across Italy

INNOVATION AND GENIUS

Overcoming the

toughest of all challenges

In the world of packaging, cardboard has overcome this challenge and reached the summit.

Today, it is the most widely used packaging material of all, owing to its qualities, which include its great protection capacity, its light weight, its easy branding and easy storage. And last but not least, its cost, which is highly competitive.

Number one in industrial packaging too

It has also overcome the challenge in industrial packaging.

A succession of ingenious innovations has led to the production of the triple wall corrugated cardboard, the benefits of which have propelled it to surpass wood, metal, plastic and all other materials.

Paper resounds

It starts with paper, which was invented to wrap objects and protect them before being used to write on. This art-form was learned in the West around the year 1000 but it only spread on a large scale during the 15th Century, after the introduction of printing. Parchment, made with sheep’s skins, was no longer enough.

boxes

per day

Today, Italy produces 11 billion cardboard boxes per year,

i.e. 30,136,986 per day.

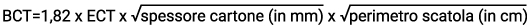

CORRUGATED CARDBOARD

Checkmate

in 4 moves

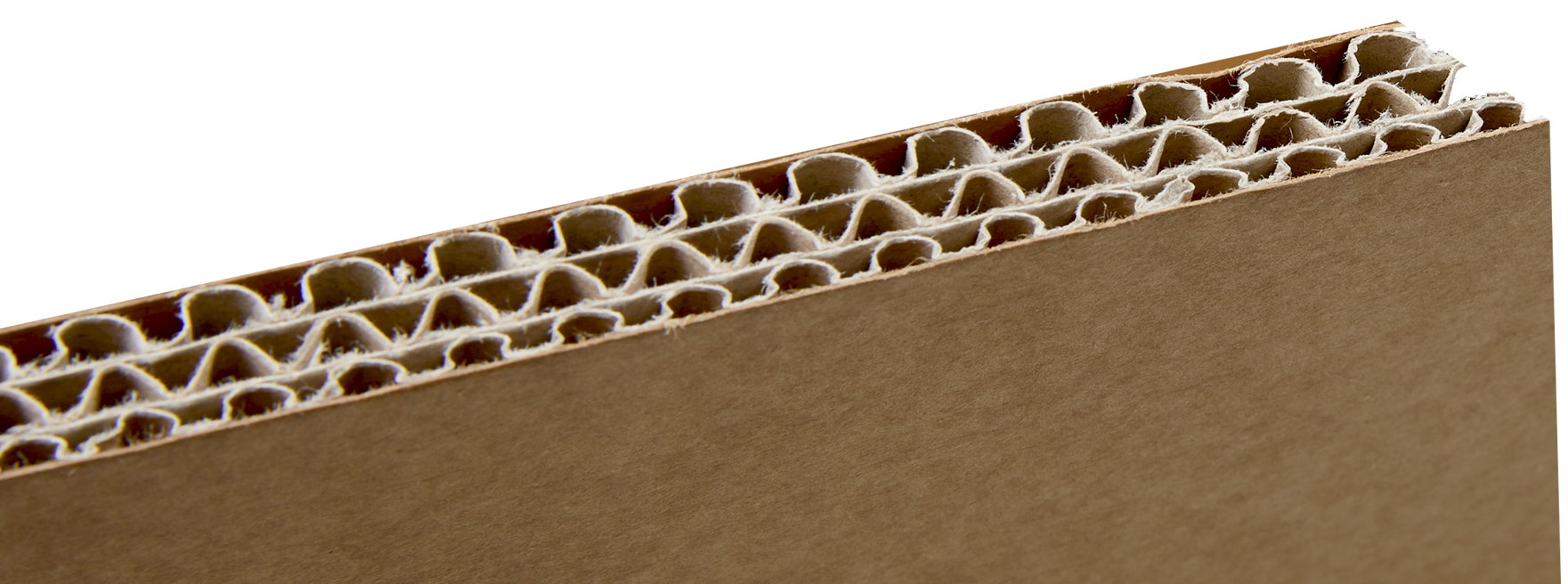

The story of corrugated cardboard is shorter than that of paper – in just 19 years, from 1856 to 1875, it went from the patent for corrugated paper to one for corrugated cardboard.

Corrugated paper patent,

Charls Healey – Eduarda Allen

Use of corrugated paper to protect glass bottles

Albert Jones

Addition of liner paper to corrugated paper

Oliver Long

Corrugated paper patent with the addition of the second layer

J.H. Thompson

The pivotal trio

After a long break, lasting some 80 years, the US Armed Forces got the idea of replacing the heavy and rigid wooden mule packsaddles, used in the Vietnam War, with lighter cardboard ones. However, to walk along the jungle trails and cross the Indochinese rivers, the cardboard had to be robust, waterproof, durable and flexible.

Columbus’s egg

Thus came the idea: to multiply everything by 3.

Columbus’s egg

The champion was born!

Strong Export®

Two inner liner boards separate three corrugated layers of different heights sandwiched between two outer liner boards.

Exceptional triple wall corrugated cardboard for Industrial Packaging was born.

A winning idea that has given rise to a REVOLUTIONARY product

The Packaging revolution

The Packaging revolution

The unhindered ascension to power

Paper along with a lot of ingenuity have created a simple product that has proven itself to be suitable for the most complex uses. Its qualities immediately emerged, gaining momentum on a difficult and lazy market for innovations such as packaging and bringing about the soft revolution of industrial packaging.

Three top qualities

Among the many qualities which have made triple wall corrugated cardboard a success, THREE (again the perfect number rule) stand out from the rest: strength, impermeability, lightness, and flexibility.

Strong

Hard-wearing strength is one of the fundamental qualities of good industrial packaging that truly has to protect the goods.

Triple wall corrugated cardboard supports unit loads ranging from 100 to 2000 kg.

Car weight 1800 kg.

Kraftliner is the ideal paper for use in Industrial Packaging.

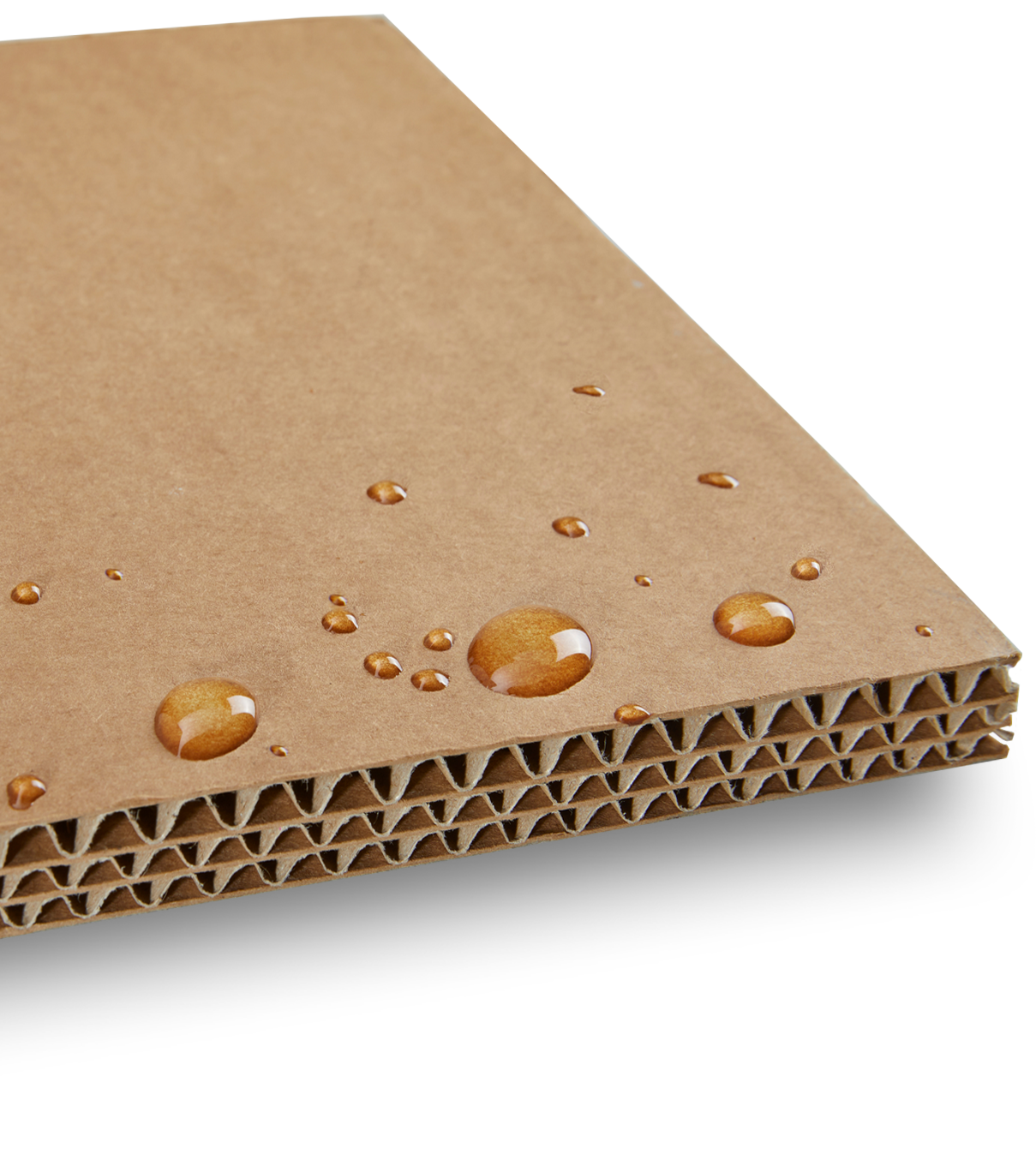

Waterproof

We are talking about Strong Export® packaging, a packaging that must guarantee its contents for long journeys. A high degree of impermeability is essential. So, to offer a winning product, the quality of the paper and glues with which the cardboard is made comes into play. This is where the guarantees delivered by the materials apply.

Industrial utility and integration

Lightweight and Flexible

Lightweight for a lighter footprint also means less waste because it’s not only useful and convenient, but also stylish. Flexibility also plays its part, in other words the ability to adapt to multiple shapes during design and to absorb shocks during transport.

THE OTHER STRENGTHS

A united effort

created a giant

There are many characteristics that have made cardboard the champion of modern packaging.

A good start

Industrial Packaging started off with triple wall corrugated cardboard immediately, producing to an American patent with the capacity of Italian excellence. Considering the excellence of the product, we had to inject the same creativity, innovation and quality into the organisation too.

A WINNING CHOICE AND A BETTER ORGANIZATION

Number One

in Italy

Betting on the triple wall corrugated cardboard immediately was a natural and winning decision for Industrial Packaging.

There’s a little secret, or two, here as well.

The first is the realisation that to work with an absolutely excellent product, an equally excellent organisation was required.

The second was to offer customers an organisation capable of having an industrial vision and of working with quality on demand.

Professionalism and technology

Bespoke packaging

Prototyping

Design

The third secret:

quality above all

For Industrial Packaging, quality has always been an obsession, a relentless pursuit of perfection.

The third secret:

quality above all

To achieve it, every component and phase must have the connotations of excellence. Everything: materials, design, production, service and the environment must be of the highest quality.

Quality of making, quality of choosing, quality of serving.

BEING GREEN

Protects the goods,

protects the environment

Eco-consciousness isn’t just about appearances; cardboard is the real deal! “Sustainable” also means tomorrow. For those who come after us.

Sustainable is “…a development that meets the needs of the present without compromising the ability of future generations to satisfy their own.”

ARE WE MAKING OURSELVES CLEAR?

They look up to us so let's do ourselves credit!

Loving our children means being sustainable in its three dimensions: economic, social and environmental. Industrial Packaging is sustainable! Cardboard is environmentally-friendly.

DATA CONQUERS DOUBT: THE POWER OF NUMBERS TO SILENCE SCEPTICS

Is cardboard Green?

That’s the right question and the answer is short and sweet: YES! Cardboard is environmentally friendly. Cellulose packaging is, in fact, a perfect example of circular economy.

Recyclable

Biodegradable

Using recycled material

Sustainable forest management

Strong Export®

Global Markets

Industrial packaging is a life on the road, or rather on the routes. It is reminiscent of Phileas Fogg’s feat of travelling around the World in 80 days.

Boundless steppes and plains, oceans, forests, skies and mountains. By ship, train, road and plane, on pallets or in containers.

An adventurous life for which you need to be well organised.

Logistics,

the crucial link

Just in time

Logistics: what gets things done

Industrial Packaging is a key component of logistics but logistics is not packaging and packaging is not logistics.

Neither is the warehouse, nor the lorry nor the road, nor the sea and the ship, nor everything that revolve around it. Logistics is all you need to make things happen efficiently.

Industrial Packaging understands this and provides the customer with a logistics service that is, first and foremost, logistics EXPERTISE, the practical consequences just follow.

Different orders, different answers

Spot orders do not require any logistical arrangements; the principal is responsible for everything.

It’s quite a different story for the other orders, both scheduled and open, according to the classification (different profiles) of Industrial Packaging.That’s when logistics definitely matter. Industrial Packaging offers its vision of “predictive logistics” with the construction of forecasting models that deploy authentic just in time logistics.

Result

Real-time deliveries and minimum warehousing, significant organisational and economic benefits for the business, as well as significant environmental benefits.